For over 20 years, Grand America Jukebox has performed Vintage Chest Type Soda Machine Restoration for clients all over the world

Let Grand America Jukebox perform a Vintage Chest Type Soda Machine Restoration or Repair for you

Grand America Jukebox in St Louis, MO Restores and Repairs

1935 – 1966 Vintage Chest Type Soda Machines

Made By Westinghouse, Cavalier, Ideal And Glasco

Not sure what model Chest Cooler you have?

First locate the metal ID tag fastened to the cabinet. You will need the Manufacture and Model number from that Metal ID tag, to choose a selection below

Where is the Metal ID tag located?

For chest type, “Self Serve” coolers (models without a coin mechanism), the Metal ID tag is mounted outside the cabinet (on the back), just above the compressor area. For chest type “Coin Operated” models, the Metal ID tag is mounted outside the cabinet, on the right or left side

What the Chest Type Model numbers mean?

Here are examples of Chest Type Soda machine model numbers

Self Serve Coolers:

Most “Self Serve” (models without a coin mechanism) cooler model numbers begin with the first letter of the manufactures name, followed by the type, then how many “Cases” of bottles that cooler will hold. The larger the model number, the larger the machine

“WE” – Westinghouse Electric cooler

“WD” – Westinghouse Dry cooler

“WH” – Westinghouse Horizontal cooler

WE-6, WD-10, WH-12, etc

Coin Operated Chest Type models:

Most “Coin Operated” Chest Type soda machine model numbers begin with the manufactures name (or abbreviation), followed by how many “Individual” bottles they will hold in the vending rack. The larger the model number, the larger the machine

Ideal 35, Ideal 55, Ideal 85, GBV 50, etc

Select a Chest Type Soda Machine model below to see photos, information and pricing

Coca Cola Westinghouse WD-12 / WH-12

Contact us

636-928-1010

doc2stat@yahoo.com

Westinghouse WE-6 Coca Cola Machine Restoration

Westinghouse WE-6 Coca Cola Machine Restoration and Repair. This Westinghouse WE 6 Coca Cola Machine arrived with a solid cabinet. However, missing many parts, which we fabricated for our client

After much fabrication and a Full Restoration, this Westinghouse WE-6 Coca Cola Machine looks, and operates better than new

The original top for this Westinghouse WE-6 Coca Cola Machine was complete but, in rough shape

After a Grand America Jukebox Full Restoration, the top for this Westinghouse WE-6 Coca Cola Machine looks factory fresh

Inside the Westinghouse WE-6 Coca Cola Machine before shows pretty rough, missing parts, bad gaskets and rusted out lid liners

Inside the Westinghouse WE-6 Coca Cola Machine after our Full Restoration shows clean with new gaskets, lid liners and a new cooling system

The original “View” window in this Westinghouse WE-6 Coca Cola Machine was missing the glass and the Coca Cola sign

For this Westinghouse WE-6 Coca Cola Machine, we re-chromed the window frame and bottle opener, replaced the window glass, and added the correct Coca Cola and Ice Cold signs

Back side of the Westinghouse WE-6 Coca Cola Machine before, shows completely empty, missing the cooling system and all the protective covers

We began by building a new, complete commercial grade cooling system for this Westinghouse WE-6 Coca Cola Machine

We then custom built new protective covers for the compressor area, wiring, and refrigeration lines of this Westinghouse WE-6 Coca Cola Machine

After body work and paint, the back side of this Westinghouse WE-6 Coca Cola Machine looks better than new

One of the top lids had rusted through for this Westinghouse WE-6 Coca Cola Machine

We cut out the rusted area enough, to get to re-usable metal

We fabricated a replacement section, and welded into place on the old lid

After body work and paint, it not only looks great but, works great as well

Both lid liners were rusted beyond repair, in this Westinghouse WE-6 Coca Cola Machine. On many Vintage Chest Type Coke machines, the lid hinges mount to the lid liners, making them an important part of the main support. We fabricated new lid liners, based off the originals

The cap catcher was the last item missing. The cap catcher was often used as a drain pan, in these Vintage Chest Type Coke Machines. So, they are commonly missing or rusted beyond repair, and need replacing. Westinghouse used many different sizes of this drawer style cap catchers

Disassembly of the Westinghouse WE-6 Coca Cola Machine

After sandblasting the cabinet

After body work and paint

After new insulation

We cleaned the original stainless steel liner, installed it and added new gaskets

The Westinghouse WE-6 Coca Cola Machine was originally filled with water, chilled by an electric cooling system. It was the first “Electric” style cooler (“E” for Electric). For this client, we replaced the water cooling unit with a new, air cooling system. Though, you could go without a cooling system and just use this as an ice cooler

The Westinghouse WE-6 Coke Machine before

And a Fully Restored Westinghouse WE-6 Coca Cola Machine after. Our client chose the solid red paint scheme with white lettering, which was factory finish for this model. However, the later Chest Type Coke Machine models did come in two-tone (red and white paint), either of which you can choose when we restore your Coke Machine

Touch Here For History of Westinghouse Coke Machines In 1935 (following the repeal of prohibition), Westinghouse introduced many models of “Chest Type” self serve Coke machines for commercial use. For sales purposes, these models were named (starting from smallest to largest) Junior = Smallest size cooler, one “Rectangular” lid, 51 bottles Standard = Double size cooler, two “Rectangular” lids, 102 bottles Master = Extra large double cooler, two “Square” lids, 144 bottles Giant = Largest size cooler, four lids, 240 bottles These model names were only used in the sales brochures, never appearing on the Coke machines, and continued production through 1941 Each was available in either “Ice” or “Electric” Refrigerated Chilled Water versions called a “Sweet Water Bath” (Sweet Water meant “Fresh” water). The “Electric” series, chilled water coolers used a stainless steel liner, filled with water. The bottles of Coke were submerged in the water, and the water was chilled by an electric cooling system. Customers had their choice of Westinghouse or Frigidaire cooling systems. Westinghouse offered both “Ice” and “Electric” options not just for cost reasons, but because electricity was not yet available to all in the late 1930’s In 1942, Westinghouse introduced a new body style of Chest Coke Machine (often referred to as the “Bow Out” style cabinet). (So named, because from all angles, the cabinet seems to be bowing or bulging outward). It was at this time, Westinghouse began the use of model numbers. Each model number began with two letters, which indicated the manufacture, and the type of cooling (how the machine chilled Coke bottles) “WI” for Westinghouse Ice cooler “WE” for Westinghouse Electric cooler These letters would then be follow by a number, which indicated how many “Cases” of Coke bottles that cooler held, (3 for three cases, 5 for 5 cases, etc.) Example: WE-6 The “WE” series with a (new cabinet design), featured a glass window with chrome trim, to view the cold bottles inside being cooled by the water, without having to open the lid. A lighted window was optional. The new cabinet style also featured an internal bottle opener and extra deep cap catcher drawer. This was for a sleeker look and to help avoid spilled caps when emptying. The cap catcher drawer also concealed the drain hose. Because of public health reasons, the “WE” series began phasing out around 1948 – 1950, (the water inside the coolers was rarely cleaned or replaced by the owners, and it was a messy job). In 1947, the “WD” series was introduced as a replacement for this problem “WD” for Westinghouse Dry cooler Example: WD-10 The “WD” series featured a galvanized liner and a cooling system that chilled the air, (like we use today in our refrigerators). The WD series used the same size cabinets as the “WE” series. However, with redesigned lids and no view window. The cap catcher drawer now also served as a drain pan. The “WD” series also featured a redesigned and deeper cooling space inside, allowing for more bottle storage. For example, this turned the 6 case cooler into a 10 case cooler, yet with the same outside cabinet dimensions to keep floor space to a minimal (which was very important for stores). Westinghouse increased the inside cooling space for each model, in an effort to hold more bottles. By the early 1950’s, the 6-case cooler could hold 12 cases. The “WD” series was manufactured to around 1954 Around 1955, Westinghouse introduced a new Westinghouse cooling system, featuring a “Finger tip” temperature knob, (customers could now adjust the temperature themselves, no tools needed) a new hermetically sealed compressor and redesigned system. Boasting the “Coldest Cokes Ever”, and automatic defrost. The new system also allowed for easier parts removal, making repairs quicker. This new cooling system was installed in all new chest type and upright Westinghouse Coke machines, and was indicated by model numbers ending in the letter “T” With a new cooling system, Westinghouse introduced a new line of upright Coke machine models. And re-designated all chest type Coke machines as “Horizontal” models. The “WD” series was now replaced by the “WH” series “WH” for Westinghouse Horizontal cooler Example: WH-12T The WH series used the same size cabinets and lids as the WD series. However, with the new cooling system, the rear of the cabinet was redesigned for simpler installation and repair. The cooling lines were moved from the left side rear, to center (which allowed for a much smaller rear compressor panel). The rear Coca-Cola lettering was changed from one large script, to two small scrip’s (one on each side of the cooling lines). The inside drain was moved from over the cap catcher drawer, to front center. The “WH” series was the last of the rounded “Bow Out” style Horizontal coolers, produced by Westinghouse. It was manufactured until around 1966, when it was replaced with the modern, boxy looking horizontal type coolers we see today. The Westinghouse WE-6, WD-10, WD-12 and WH-12T Coca Cola Machines all use the same size “Bow Out” Style cabinet Dimensions: 36″ Tall, 45″ wide, 28″ deep But, each features different depth cooling areas and lids For paint schemes, the Westinghouse “WI”, “WE”, “WD” series (and early versions of the Westinghouse “WH” series) Coca Cola Cooler Machines all came in Solid Red paint with white lettering, from the factory. Later versions of the Westinghouse “WH” Coca Cola Machines came in Two-Tone paint. Basically, most Coca Cola Machines built from 1935 – 1955, were Solid Red. Most Coca Cola Machines built from 1956 and later, were Two-Tone. Westinghouse Coca Cola Machines are difficult to establish a date of manufacture. Westinghouse Serial Numbers were used for parts identification only, and did not include the date of manufacture Westinghouse and Cavalier both manufactured chest type coolers for Coca Cola, and look very similar. However, the Bow Out body style cabinets (1942-1966) for each, do have small noticeable differences. The Westinghouse models feature an internal bottle opener with cap catcher drawer/drain pan. The Cavalier models feature and external bottle opener, external cap catcher and a separate drain pan drawer The Westinghouse WE-6 Coca Cola Machine originally held 6 cases of the small, Coke bottles “W” for Westinghouse “E” for Electric cooling system “6” for 6 cases The Westinghouse WE-6 Coke Machine is a “Self Serve” Horizontal type cooler, (non-coin operated). To operate, a customer would open the cooler lid, grabbed a bottle of Coke, then pay a cashier. Because the Westinghouse WE-6 Horizontal cooler has no actual vending mechanism, it can hold and cool almost anything, even food. For liability reasons, we cannot repair any water chilled cooling systems. These must be removed to use as an Ice Box, or converted to an Air Cooled system Grand America Jukebox offers two options for YOUR Westinghouse WE-6 Coke Machine Full Restoration of Your Westinghouse WE-6 with new cooling system starting at $8295.00 est Full Restoration of Your Westinghouse WE-6 as an Ice Box starting at $6295.00 est Or, we can Partially Restore your WE-6 starting at $4295.00 est View our Vintage Soda Machine page to see everything included in both Full and Partial Restorations

Contact us

636-928-1010

doc2stat@yahoo.com

Westinghouse WD-12 & WH-12 Coca Cola Machine Restoration

Westinghouse WD-12 Coca Cola Machine Restoration and Repair. This Westinghouse WD-12 Coca Cola Machine arrived with a solid cabinet but, in rough shape

After a Grand America Jukebox Full Restoration, this Westinghouse WD-12 Coca Cola Machine looks and works better than new

The Westinghouse WD-12 Coca Cola Machine originally came in solid Red paint. Our client chose the later Two-Tone paint option

Inside the Westinghouse WD-12 Coca Cola Machine before, was pretty rough. The gaskets were bad, fiberglass lid liners had cracked and the cooling system did not work

After our Full Restoration, shows all new gaskets, new plastic lid liners and a new, complete commercial grade cooling system. The Westinghouse “WD” series was the first to use a “Dry” cooling system that chilled the air (“D” for Dry) rather than water

Back side of the Westinghouse WD-12 Coca Cola Machine before, shows a non-functional cooling system, and a missing compressor cover

Back side of the Westinghouse WD-12 Coca Cola Machine after our Full Restoration, shows the new cooling system installed

Because the rear compressor cover was missing, we had to fabricate a new one

After bending our cut pieces, welding it together, we adjust to fit before paint

After body work and paint, the back side of the Westinghouse WD-12 Coca Cola Machine looks complete and factory fresh

Inside the cooling area liner of the Westinghouse WD-12 Coca Cola Machine before. We removed the old cooling system and gaskets, then removed the main liner and all insulation

Next, we removed the rusted out cabinet bottom, sandblasted the whole cabinet, performed body work and painted, then fabricated a new cabinet bottom

We installed new insulation and supports, then the restored liner and drain assembly, all new gaskets and the new cooling system. After installing the restored top lids, adjusting the thermostat and running for at least 24 hours, we have a Fully Restored Westinghouse WD-12 Coca Cola Machine ready to ship back to our client

Here is our Fully Restored Westinghouse WD-12 Coke Machine. For this Coca Cola machine, our client chose the factory finish, solid red paint scheme with white lettering. The later “WH” series Horizontal Type Coke Machine models did come in two-tone (red and white paint), either of which you can choose when we restore your Coke Machine

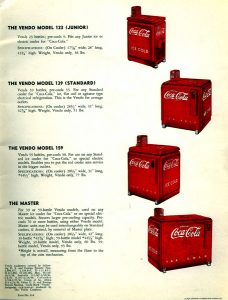

Touch Here For A Brief History of Westinghouse Coke Machines 1935: Following the repeal of prohibition, Westinghouse introduces many models of “Chest Type” self serve Coke machines, for commercial use. For sales purposes, these models were given names (starting from smallest to largest) Junior = Smallest size cooler, one “Rectangular” lid, 51 bottles Standard = Double size cooler, two “Rectangular” lids, 102 bottles Master = Extra large double cooler, two “Square” lids, 144 bottles Giant = Largest size cooler, four lids, 240 bottles This brochure shows the late 1930’s Westinghouse Coca Cola cooler models with a “Vendo” coin operated top. Though, these same cooler models came direct from Westinghouse with simple lift lids These sales model “Names” were only used in the sales brochures (never appearing on the Coke machines), and continued production through 1941 Each was available in either “Ice” or “Electric” Refrigerated Chilled Water versions called a “Sweet Water Bath” (Sweet Water meant “Fresh” water). The “Electric” series, chilled water coolers used a stainless steel liner, filled with water. The bottles of Coke were submerged in the water, and the water was chilled by an electric cooling system. Customers had their choice of Westinghouse or Frigidaire cooling systems. Westinghouse offered both “Ice” and “Electric” options not just for cost reasons, but because electricity had not yet reached rural areas by the late 1930’s 1942: Westinghouse introduced a new body style of Chest Coke Machine (often referred to as the “Bow Out” style cabinet. So named, because from all angles, the cabinet seems to be bowing or bulging outward). It was at this time, Westinghouse began the use of model numbers. Each chest type Coke machine model number began with two letters, which indicated the manufacture, and the type of cooling (how that machine chilled Coke bottles) “WI” for Westinghouse Ice cooler “WE” for Westinghouse Electric cooler These letters would then be follow by a number, which indicates how many “Cases” of Coke bottles that cooler held, (3 for three cases, 5 for 5 cases, etc.) Example: WE-6 Westinghouse WE-6 Coca Cola Cooler The “WE” series (with a new cabinet design), now featured a glass window on the top, with chrome trim, to view the cold bottles inside being cooled by the water, without having to open the lid. A lighted window was optional, (though the window was fazed out on later WE series coolers, replaced by full length lids). Stainless Steel lids were optional. The new cabinet style also featured a recessed bottle opener and extra deep cap catcher drawer. This provided a streamlined look, and helped to avoid spilling bottle caps when emptying. The cap catcher drawer also concealed the drain hose. Because of public health reasons, the “WE” series began phasing out around 1948 – 1950, (the water inside the “Electric” coolers was rarely cleaned or replaced by the owners, and it was a messy job) 1947: Westinghouse introduces the “WD” series electric cooler to replace the “WE” series “WD” for Westinghouse Dry cooler Example: WD-10 Westinghouse WD-10 Coca Cola Cooler Essentially, the “WD” series looks the same as the “WE” series, with a few small modifications. The “WD” series features a galvanized liner (instead of stainless steel), and a cooling system that chills the air (instead of water), like we use today in our refrigerators. The WD series uses the same size cabinets as the “WE” series, with full length lids that cover the whole top (having no need for a view window). The WD-10 Coca Cola Cooler featured an exterior mounted bottle opener and cap catcher, while other models retained the drawer style and recessed bottle opener. Though the cap catcher drawer would now also serve as a drain pan. The “WD” series also features a redesigned and deeper cooling space inside, which allows for more bottle storage that previous models. For example, this changes the 6 case cooler into a 10 case cooler, while keeping the same outside cabinet dimensions, which kept floor space to a minimal (this was a very important sales point for stores). Westinghouse increased the inside cooling area for each model, in an effort to hold more bottles. By the early 1950’s, the original 6-case cooler cabinet could now hold 12 cases Example: WD-12 Westinghouse WD-12 Coca Cola Cooler The “WD” series was manufactured to around 1954 1955: Westinghouse introduces a new Westinghouse cooling system, featuring a “Finger tip” temperature knob, (customers could now adjust the temperature themselves, no tools needed) a new hermetically sealed compressor and redesigned system. Boasting the “Coldest Cokes Ever”, and automatic defrost. The new system also allowed for easier parts removal, making for quicker repair times. This new cooling system was installed in all new chest type and upright Westinghouse Coke machines, and was indicated with model numbers ending in the letter “T” With a new cooling system, Westinghouse introduced a new line of upright Coke machine models, and re-designated all chest type Coke coolers as “Horizontal” coolers. The “WD” series was now replaced by the “WH” series “WH” for Westinghouse Horizontal cooler Example: WH-12T Westinghouse WH-12T Coca Cola Cooler Again, the Westinghouse “WH” series Coke coolers look basically the same as the “WD” series Coke coolers, with a few small modifications. Stainless Steel lids were optional. The big changes came to the rear of the cabinet because of the new cooling system, and to make for simpler installation and repair Westinghouse WD-12 Coke Cooler rear cabinet Westinghouse WH-12T Coke Cooler rear cabinet The cooling lines were moved from the left side rear, to center (which allowed for a much smaller rear compressor panel). The rear Coca-Cola lettering was changed from one large script, to two small scrip’s (one on each side of the cooling lines). The inside drain was moved from over the cap catcher drawer, to front center 1956: Coca Cola introduces a new advertising campaign focusing on a fresher new look. From 1956 on, Coke machines are offered in two-tone paint. Beginning in 1956, the Westinghouse WH-12 features the new two tone paint scheme Westinghouse WH-12T Coca Cola Cooler in two-tone paint The “WH” series was the last of the rounded “Bow Out” style Horizontal coolers, produced by Westinghouse, and were manufactured until around 1966. It was replaced with the modern, boxy looking horizontal type coolers we see today. The Westinghouse WE-6, WD-10, WD-12 and WH-12T Coca Cola Machines all use the same size “Bow Out” Style cabinet Dimensions: 36″ Tall, 45″ wide, 28″ deep But, each features different depth interior liners and lids Westinghouse Coca Cola Machines are difficult to establish a date of manufacture. Westinghouse Serial Numbers were used for parts identification only, and did not include the date of manufacture The Westinghouse WD-12 Coca Cola Machine is a Horizontal type cooler, and originally held 12 cases of the small Coke bottles. “W” for Westinghouse, “D” for Dry cooling system, “12” for 12 cases. The Westinghouse WD-12 and WH-12 Coke Machines are “Self Serve” Horizontal type coolers (non-coin operated). To operate, a customer would open the top cooler lid, grabbed a bottle of Coke, then pay a cashier. Because the Westinghouse WD-12 and WH-12 have no actual vending mechanism, they can hold and cool almost anything, even food Grand America Jukebox offers two options for YOUR Westinghouse WD-12/WH-12 Coke Machine Full Restoration of Your Westinghouse WD-12 or WH-12 starting at $8295.00 est Or, we can Partially Restore your WD-12 / WH-12 starting at $4295.00 est View our Vintage Soda Machine page to see everything included in both Full and Partial Restorations

Contact us

636-928-1010

doc2stat@yahoo.com

Glasco Slider Coca Cola Machine Restoration

Glasco Slider Coca Cola Machine Restoration and Repair. This Glasco GBV50 Coca Cola Machine arrived in solid shape but, in need of restoration. It had been repainted and re-decaled, sometime in the mid 1960’s. After a Grand America Jukebox Full Restoration, this Glasco Coca Cola Slider now features the correct Coca Cola “Fishtail” logo, it looks fantastic and works good as new

Before, the top lid and scuff plate on this Glasco Coca Cola Machine, were dented, and all gaskets were bad

After, we replaced the top lid and scuff plate with new stainless steel, added a new chrome handle, all new rubber gaskets and chromed the rear lid supports

Inside the top lid of this Glasco Slider Coca Cola Machine before, shows worn gaskets, worn decal and in need of restoration. This Glasco Slider was missing the original coin mechanism and bottle “Slider” rack

Inside the top lid of this Glasco Slider Coca Cola Machine after our Full Restoration, shows all new gaskets, new top lid and decal, we fabricated a new, full size shelf and plugged the original coin mechanism holes. Most clients request the original “Slider” rack be removed for this model, to allow for more space. Providing a nice, clean open area to cool any size bottle, cans or even food if you wish

Inside view of the side loading door on this Glasco Slider Coca Cola Machine before, shows dirty and dingy. This side door originally gave access to loading the bottle “Slider” rack, and the bottle Pre-Cool area below. After our Full Restoration, it looks better than new and will actually store more. We removed the un-needed lower shelf, to expose a much larger pre-cooling area. This Glasco Slider Coca Cola Machine can now hold many cases. Cold beverages, ready to serve, go on top of the shelf. Warmer beverages go below to be Pre-Cooled. We also replaced the side loading door gasket and black breaker strips

Restoration Process

We completely dis-assemble all soda machine cabinets, and sand blast to bare metal, perform bodywork and paint, fabricate and install a new cabinet bottom

We install new insulation, the restored liner, all new gaskets and breaker strips

We then install a new commercial grade compressor, fan motor, thermostat and all new wiring

(Note: As of 2015, these NEW Slider type complete cooling systems are no longer available. However, we have access to a limited supply of brand NEW compressors to restore your original Glasco Slider cooling system)

After installing the top lid, side door, and chrome, this Glasco Slider Coca Cola Machine is ready for years of new use

Grand America Jukebox offers two options for YOUR Glasco Slider Coke Machine

Full Restoration of Your Glasco GVB 50 Slider: $5995.00

Full Restoration of Your Glasco GBV 50 Slider with a NEW compressor: $7495.00

Or, we can Partially Restore your Glasco GVB 50 Slider for: $1995.00

Partial Restoration of your Glasco GVB 50 Slider with a NEW compressor for: $3495.00

View our Vintage Soda Machine page to see everything included in both Full and Partial Restorations

Contact us

636-928-1010

doc2stat@yahoo.com

Glasco Slider Coke Machine History And Serial Numbers

The Glasco Slider Coca Cola Machine was first introduced in late 1957 for the 1958 model year, under the sales name “Starlet”. The model number is GBV50 (Glasco Beverage Vendor holding 50 bottles). Originally, there was a coin mechanism mounted to the left side of the machine. You would open the top lid to view your selections (all bottles hanging by their necks, with their flavors displayed on the bottle caps). Once a selection was chosen, you would insert a coin in the coin mechanism. You would then grab the bottle cap and “Slide” it down the rack to a “Butter Fly” release. The coin would mechanically allow you to pull the bottle through the butter fly release. It is the action of Sliding the bottle that gave this machine its designation as a “Slider”

The Coca Cola “Fishtail” logo was also introduced for the 1958 year. Glasco manufactured the “Starlet” through 1962 (that we have found). The early versions used metal lid and door liners, while the later versions used plastic liners

Glasco did not document any serial numbers for the Coca Cola Slider (that we have found). However, they did use good quality Tecumseh cooling systems and those do have date codes. Using both the external cabinet serial numbers and the Tecumseh compressor date codes, we have assembled the following list, to help date your Glasco GBV 50 Slider Coca Cola Machine

Serial# GBV50 Slider Years

2638 May 19, 1957, This was the earliest GBV50 version we found, metal door liner

4340 June 10, 1959

4911 June 19, 1959

10562 Feb 29, 1960 Compressor date B 29 60, Base plate 6C0

12359 March 3, 1960 Compressor date C 03 60, Base plate 6C0

13794 May 13, 1960 Compressor date E 13 60, Base plate 6E0

16868 June 29, 1960 Compressor date F 29 60

25666 June 11, 1962 Compressor date code F 11 62, Plastic door liners

The Glasco GBV50 Slider Coca Cola Machine is a chest type machine that originally held 50 bottles (6-8 oz size) or 45 bottles (12 oz size) in the top lid vending area. It offered these in 5 slots or selections (10 bottles to each selection). It holds another 60 or so bottles, (for pre-cooling) through the side loading door

Dimensions: 38″ Tall, 33″ wide, 18″ deep (cabinet only)

Contact us

636-928-1010

doc2stat@yahoo.com

Ideal 55 Slider Pepsi Machine Restoration

Ideal 55 Slider Pepsi Machine Restoration and Repair. This Ideal 55 Slider Pepsi Machine arrived complete but, in need of restoration

After a Grand America Jukebox Full Restoration, it looks and works better than new

Before, the original top lid on this Ideal 55 Slider Pepsi Machine, had been covered with shelf paper to hide dents and scratches

We replaced the top lid and scuff plate with new stainless steel, installed a new chrome handle, all new gaskets and had the rear lid supports chrome plated

Inside the top lid of this Ideal 55 Slider Pepsi Machine before, shows the original “Slider” rack (this was the vending mechanism for this machine) and worn out gaskets

Inside the top lid after our Full Restoration, shows the Slider rack removed, new gaskets, and the coin mechanism holes plugged. Most clients request the “Slider” rack be removed for this model, to allow for more room. Providing a nice, clean open area to cool any size bottle, cans or even food if you wish

Restoration Process

We completely dis-assemble all soda machine cabinets, sand blast to bare metal, perform bodywork and paint, fabricate and install a new cabinet bottom

We install new insulation, the restored liner, all new gaskets and breaker strips

We then install a new commercial grade compressor, fan motor, thermostat and all new wiring

(Note: As of 2015, these NEW Slider type cooling systems are no longer available. However, we have access to a limited supply of brand NEW compressors to restore your original Ideal Slider cooling system)

After installing the new top lid, side door and chrome, this Ideal 55 Slider Pepsi Machine is ready for years of new use

Grand America Jukebox offers many options for YOUR Ideal 55 Slider Soda Machine

Full Restoration of Your Ideal 55 Slider: $5995.00

Full Restoration of Your Ideal 55 Slider with a NEW compressor: $7495.00

Or, we can Partially Restore your Ideal 55 Slider for: $1995.00

Partial Restoration of your Ideal 55 Slider with a NEW compressor for: $3495.00

View our Vintage Soda Machine page to see everything included in both Full and Partial Restorations

Contact us

636-928-1010

doc2stat@yahoo.com

Ideal 55 Slider Soda Machine History And Serial Numbers

The Ideal 55 Slider was first introduced in the late 1940’s, and manufactured through the early 1960’s. The Ideal 55 Slider is a chest type machine that originally held 50 bottles (6-8 oz size) or 45 bottles (12 oz size) in the top lid vending area. It offered these in 5 slots or selections (10 bottles to each slot). It holds another 60 or so bottles, (for pre-cooling) through the side loading door. Ideal manufactured many models of the “Slider”, including a smaller version called the Model 35, and larger versions like the Model 70 and Model 85

Ideal manufactured these models for 7-up, Royal Crown, Squirt and many, many more. However, not many for Coca Cola. Glasco made Coca Cola Sliders from 1958 thru 1962

During the time the Ideal Slider was manufactured (for around 15 years or so), many soda brands had changed their logo. Pepsi for example, had three logo changes during this time. The “Pepsi : Cola” in embossed script (ran from the late 40’s to 1950), the “Pepsi – Cola” in embossed script (ran from 1951 to about 1959) and finally the “Pepsi – Cola” on a 3-D looking plastic sign that mounted to the front of the Slider (ran from about 1960 to 1962)

Ideal did not document any serial numbers for the “Slider” (that we have found). However, they did use good quality Tecumseh cooling systems, and those do have date codes. Using both the external cabinet serial numbers and the Tecumseh compressor date codes, we are trying to assemble a list to help date your Ideal 55 Slider. Please send us photos and serial numbers from your Ideal 55 Slider, no matter what flavor it is

Dimensions: 38″ Tall, 33″ wide, 18″ deep (cabinet only)

Contact us

636-928-1010

doc2stat@yahoo.com

Ideal 85 Slider RC Machine Restoration

Ideal 85 Slider Royal Crown Soda Machine Restoration and Repair. This Ideal 85 Slider RC Machine arrived with a solid cabinet in need of restoration

After a Grand America Jukebox Full Restoration, this Ideal 85 Slider RC Machine looks and works better than new

Before, the right side loading door lock was broken and held together by a large bolt

After our Full Restoration, this Ideal 85 Slider has the correct factory look, matching cap catcher, and the side loading door lock is replaced and functional

Before, the top lid of this Ideal 85 Slider Royal Crown Soda Machine shows many dents

We fabricated a new stainless steel lid and scuff plate for this Ideal 85 Slider Soda Machine. And, re-chromed the hinges

Inside the top lid of this Ideal 85 Slider before, shows the original bottle vending rack and instruction decal

Inside the top lid of this Ideal 85 Slider after our Full Restoration, shows the functional bottle rack with authentic RC decals, new instruction decal, and new lid gasket

Inside the side loading door of this Ideal 85 Slider before, shows worn and dingy

Inside the side loading door of this Ideal 85 Slider after our Full Restoration, shows new gasket, new breakers strips, all metal has been repainted, decaled, and new door lock

Before, the cooling system for this Ideal 85 Slider still worked but, in need of restoration

We cleaned and repainted the whole cooling system, installed all new wiring, fan motor, thermostat and power cord

Before, the coin mechanism for this Ideal 85 Slider Soda Machine, arrived in pieces. After our Full Restoration, the left side looks good as new with a fully restored and functional coin mechanism

Restoration Process

We begin by dis-assembling the machine completely, the cabinet is sandblasted down to bare metal, bodywork is performed and paint is applied

New insulation is installed, followed by the restored liner and breaker strips

Restored air baffles are installed, and the re-chromed top lid hinges

The fully restored Slider rack is installed

Before, the Ideal 85 Slider coin mechanism cover had been repainted several times

We sand blasted the cover. Then, applied the original black wrinkle paint and bake it to activate the wrinkle look

Assemble the re-chromed castings, cash box lock and instruction plates

And install the fully restored coin mechanism

Assemble and install the side loading door and the new top lid

Install the fully restored cooling system and cover plate

Install the new Royal Crown bottle opener and other RC decals

After, a Fully Restored Ideal 85 Slider Soda Machine, ready for delivery

Grand America Jukebox offers two options for YOUR Ideal 85 Slider Soda Machine

Full Restoration of Your Ideal 85 Slider starting at $7795.00 est

Or, we can Partially Restore your Ideal 85 Slider starting at $2495.00 est

View our Vintage Soda Machine page to see everything included in both Full and Partial Restorations

Contact us

636-928-1010

doc2stat@yahoo.com

Ideal 85 Slider Soda Machine History And Serial Numbers

The Ideal 85 Slider was first introduced in the late 1940’s and was manufactured through the early 1960’s. The Ideal 85 Slider is a chest type machine that holds 78 bottles (6-8 oz size) or 72 bottles (12 oz size) in the top lid vending area. It offered these in 6 slots or selections (13 bottles to each slot). It also holds another 40 or so bottles (for pre-cooling) through the side loading door. Ideal manufactured many models of the “Slider”, including two smaller versions called the Model 35 and the Model 55, as well as much larger versions

Ideal manufactured these models for 7-up, Royal Crown, Squirt and many, many more. However, not many for Coca Cola. Glasco made Coca Cola Sliders from 1958 thru 1962

During the time the Ideal Slider was manufactured (for around 15 years or so), many soda brands had changed their logo. Pepsi for example, had three logo changes during this time. The “Pepsi : Cola” in embossed script (ran from the late 40’s to 1950), the “Pepsi – Cola” in embossed script (ran from 1951 to about 1959)and finally the “Pepsi – Cola” on a 3-D looking plastic sign that mounted to the front of the Slider (ran from about 1960 to end)

Ideal did not document any serial numbers for the “Slider” (that we have found). However, they did use good quality Tecumseh cooling systems and those do have date codes. Using both the external cabinet serial numbers and the Tecumseh compressor date codes, we are trying to assemble a list to help date your Ideal 55 Slider. Please send us photos and serial numbers from your Ideal 55 Slider, no matter what flavor it is

We can restore your Ideal 85 Slider in any flavor, and as a vendor or as an open type stand alone cooler with no vending mechanism. Allowing the Ideal 85 Slider to hold bottles, cans and even food

Dimensions: 39″ Tall, 46″ wide, 26″ deep